Screen

printing is a printing technique that uses a woven

mesh to support an ink blocking stencil. The attached

stencil forms open areas of mesh that transfer ink

as a sharp-edged image onto a substrate.

Screen

printing is a printing technique that uses a woven

mesh to support an ink blocking stencil. The attached

stencil forms open areas of mesh that transfer ink

as a sharp-edged image onto a substrate.

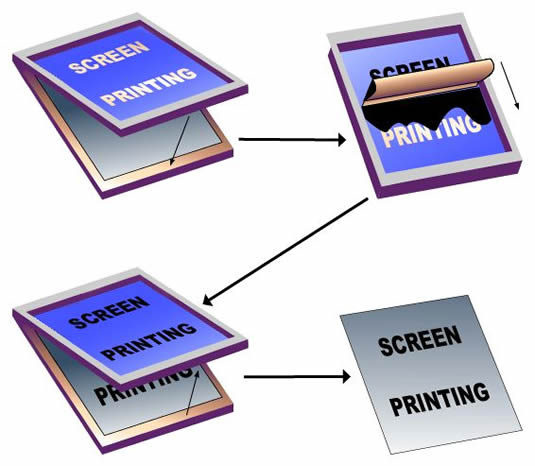

A squeegee is moved across the screen stencil forcing

or pumping ink past the threads of the woven mesh

in the open areas.

A

screen is made of porous, finely woven fabric called

mesh stretched over a frame of aluminum or wood. Originally

human hair then silk was woven into screen mesh, currently

most mesh is made of man made materials such as steel,

nylon, and polyester. Areas of the screen are blocked

off with a non-permeable material to form a stencil,

which is a negative of the image to be printed; that

is, the open spaces are where the ink will appear.

The

screen is placed atop a substrate such as polystyrene,

paper or fabric. Ink is placed on top of the screen,

and a floodbar (also known as a fill bar) is used

to fill the mesh openings with ink. The operator begins

with the floodbar at the rear of the screen and behind

a reservoir of ink. The operator lifts the screen

to prevent contact with the substrate and then using

a slight amount of downward force pulls the floodbar

to the front of the screen. This effectively fills

the mesh openings with ink and moves the ink reservoir

to the front of the screen. The operator then uses

a squeegee (rubber blade) to move the mesh down to

the substrate and pushes the squeegee to the rear

of the screen. The ink that is in the mesh opening

is pumped or squeezed by capillary action to the substrate

in a controlled and prescribed amount, i.e. the wet

ink deposit is equal to the thickness of the mesh

and or stencil. As the squeegee moves toward the rear

of the screen the tension of the mesh pull the mesh

up away from the substrate (called snap-off) leaving

the ink upon the substrate surface.

The

Screen Printing Process

There

are three types of screenprinting presses. The 'flat-bed'

(probably the most widely used), 'cylinder', and 'rotary'.

Textile

items are printed in multi-color designs using a wet

on wet technique, while graphic items are allowed

to dry between colors that are then printed with another

screen and often in a different color.

Reclaiming A Screen |

The

screen can be re-used after cleaning. However if the

design is no longer needed, then the screen can be

"reclaimed", that is cleared of all emulsion

and used again. The reclaiming process involves removing

the ink from the screen then spraying on stencil remover

to remove all emulsion. Stencil removers come in the

form of liquids, gels, or powders. The powdered types

have to be mixed with water before use, and so can

be considered to belong to the liquid category. After

applying the stencil remover the emulsion must be

washed out using a pressure washer.

Most

screens are ready for recoating at this stage, but

sometimes screens will have to undergo a further step

in the reclaiming process called dehazing. This additional

step removes haze or "ghost images" left

behind in the screen once the emulsion has been removed.

Ghost images tend to faintly outline the open areas

of previous stencils, hence the name. They are the

result of ink residue trapped in the mesh, often in

the knuckles of the mesh, those points where threads

overlap.

While

the public thinks of garments in conjunction with

screenprinting, the technique is used on tens of thousands

of items, decals, clock and watch faces, and many

more products. The technique has even been adapted

for more advanced uses, such as laying down conductors

and resistors in multi-layer circuits using thin ceramic

layers as the substrate.

Screenprinting

is more versatile than most other traditional printing

techniques. The surface does not have to be printed

under pressure, unlike etching or lithography, and

it does not have to be planar. Screenprinting inks

can be used to work with a variety of materials, such

as textiles, ceramics, wood, paper, glass, metal,

and plastic. As a result, screenprinting is used in

many different industries, from clothing to product

labels to circuit board printing.

The above text was borrowed from Wikipedia.com.